AD7818AR 查看數據表(PDF) - Analog Devices

零件编号

产品描述 (功能)

生产厂家

AD7818AR Datasheet PDF : 20 Pages

| |||

AD7816/AD7817/AD7818

For example, if the result of a conversion on Channel 0 was

1000000000 (512 Dec), the ambient temperature is equal to

–103°C + (512/4) = +25°C.

Table II below shows some ADC codes for various temperatures.

Table II. Temperature Sensor Output

ADC Code

00 1100 0000

01 0011 1000

01 1001 1100

10 0000 0000

10 0111 1000

11 1001 0000

Temperature

–55°C

–25°C

0°C

+25°C

+55°C

+125°C

TEMPERATURE MEASUREMENT ERROR DUE TO

REFERENCE ERROR

The AD7816, AD7817, and AD7818 are trimmed using a pre-

cision 2.5 V reference to give the transfer function described

previously. To show the effect of the reference tolerance on a

temperature reading, the temperature sensor transfer function

can be rewritten as a function of the reference voltage and the

temperature.

CODE (Dec) = ([113.3285 × K × T]/[q × VREF] – 0.6646) × 1024

where:

K = Boltzmann’s Constant, 1.38 × 10–23

q = Charge on an electron, 1.6 × 10–19

T = Temperature (K)

So, for example, to calculate the ADC code at 25°C

CODE = ([113.3285 × 298 × 1.38 × 10–23]/[1.6 × 10–19 × 2.5]

– 0.6646) × 1024

= 511.5 (200 Hex)

As can be seen from the expression, a reference error will pro-

duce a gain error. This means that the temperature measure-

ment error due to reference error will be greater at higher

temperatures. For example, with a reference error of –1%, the

measurement error at –55°C would be 2.2 LSBs (0.5°C) and

16 LSBs (4°C) at 125°C.

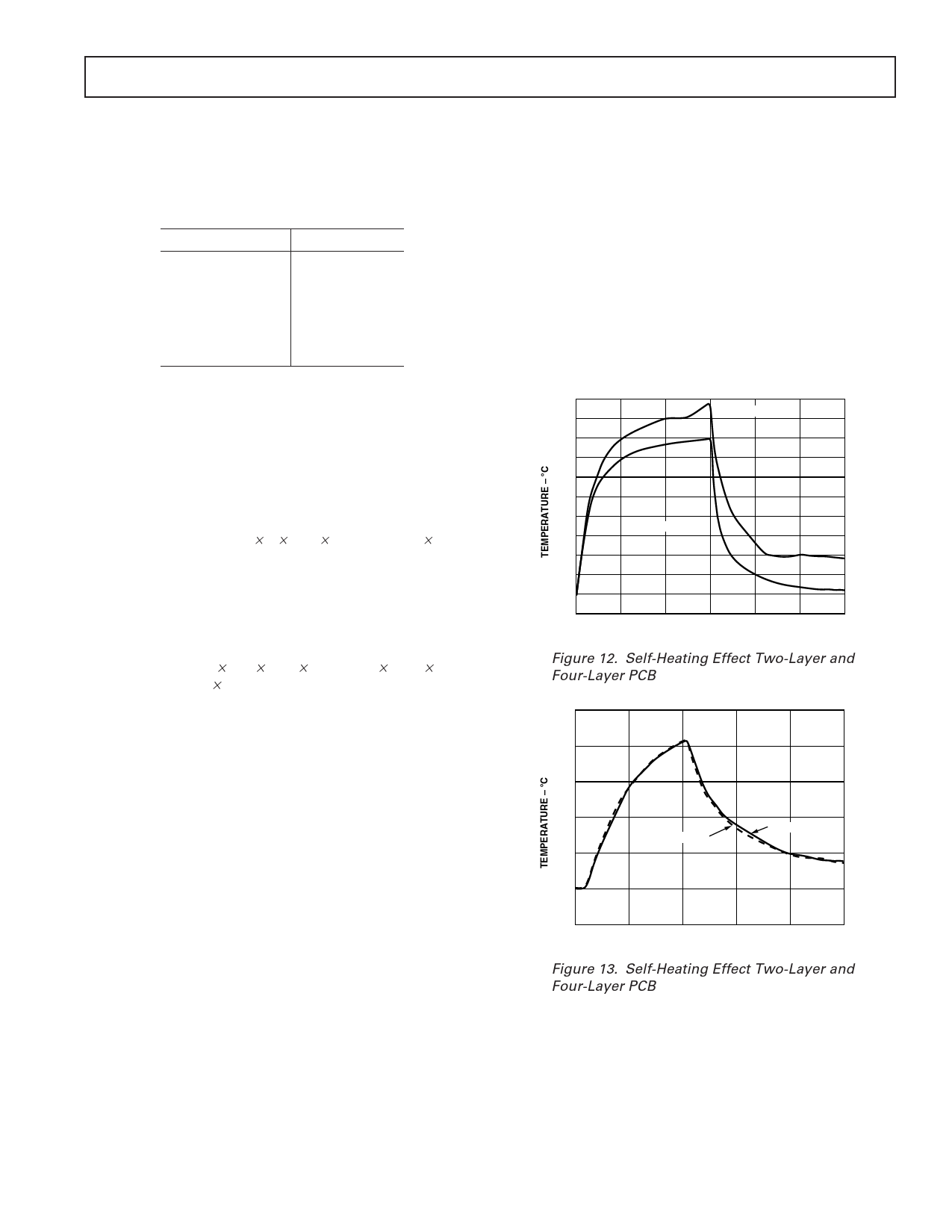

SELF-HEATING CONSIDERATIONS

The AD7817 and AD7818 have an analog-to-digital conversion

function capable of a throughput rate of 100 kSPS. At this

throughput rate the AD7817 and AD7818 will consume between

4 mW and 6.5 mW of power. Because a thermal impedance is

associated with the IC package, the temperature of the die will

rise as a result of this power dissipation. The graphs below show

the self-heating effect in a 16-lead SOIC package. Figures 12

and 13 show the self-heating effect on a two-layer and four-layer

PCB. The plots were generated by assembling a heater (resistor)

and temperature sensor (diode) in the package being evaluated.

In Figure 12, the heater (6 mW) is turned off after 30 sec. The

PCB has little influence on the self-heating over the first few

seconds after the heater is turned on. This can be more clearly

seen in Figure 13 where the heater is switched off after 2 sec-

onds. Figure 14 shows the relative effects of self-heating in air,

fluid and in thermal contact with a large heat sink.

These diagrams represent the worst-case effects of self-heating.

The heater delivered 6 mW to the interior of the package in all

cases. This power level is equivalent to the ADC continuously

converting at 100 kSPS. The effects of the self-heating can be

reduced at lower ADC throughput rates by operating on Mode

2 (see Operating Modes section). When operating in this mode,

the on-chip power dissipation reduces dramatically and, as a

consequence, the self-heating effects.

0.50

2-LAYER PCB

0.45

0.40

0.35

0.30

0.25

0.20

4-LAYER PCB

0.15

0.10

0.05

0.00

–0.05

0

10

20

30

40

50

60

TIME – secs

Figure 12. Self-Heating Effect Two-Layer and

Four-Layer PCB

0.25

0.20

0.15

0.10

2-LAYER PCB

4-LAYER PCB

0.05

0.00

–0.05

0

1

2

3

4

5

TIME – secs

Figure 13. Self-Heating Effect Two-Layer and

Four-Layer PCB

REV. C

–13–