TWR-5/1800-12/200-D48A 查看數據表(PDF) - DATEL Data Acquisition products

零件编号

产品描述 (功能)

生产厂家

TWR-5/1800-12/200-D48A

TWR-5/1800-12/200-D48A Datasheet PDF : 5 Pages

| |||

12-15W, TRIPLE OUTPUT DC/DC CONVERTERS

TWR Models

Quality and Reliability

The A-Series are the first DC/DC Converters to emerge from DATEL’s new,

company-wide approach to designing and manufacturing the most reliable power

converters available. The five-pronged program draws our Quality Assurance

function into all aspects of new-product design, development, characterization,

qualification and manufacturing.

Design for Reliability

Design for Reliability is woven throughout our multi-phased, new-product-

development process. Design-for-reliability practices are fully documented and

begin early in the new-product development cycle with the following goals:

1. To work from an approved components/vendors list ensuring the use of

reliable components and the rigorous qualification of new components.

2. To design with safety margins by adhering to a strict set of derating

guidelines and performing theoretical worst-case analyses.

3. To locate potential design weaknesses early in the product-development

cycle by using extensive HALT (Highly Accelerated Life Testing).

4. To prove that early design improvements are effective by employing a

thorough FRACA (Failure Reporting Analysis and Corrective Action) system.

HALT Testing

The goal of the accelerated-stress techniques used by DATEL is to force device

maturity, in a short period of time, by exposing devices to excessive levels of

"every stimulus of potential value." We use HALT (Highly Accelerated Life

Testing) repeatedly during the design and early manufacturing phases to detect

potential electrical and mechanical design weaknesses

that could result in possible future field failures.

During HALT, prototype and pre-production DC/DC converters are subjected to

progressively higher stress levels induced by thermal cycling, rate of tempera-

ture change, vibration, power cycling, product-specific stresses (such as dc

voltage variation) and combined environments. The stresses are not meant to

simulate field environments but to expose any weaknesses in a product’s

electro/mechanical design and/or assembly processes. The goal of HALT is to

make products fail so that device weaknesses can be analyzed and strength-

ened as appropriate. Applied stresses are continually stepped up until products

eventually fail. After corrective actions and/or design changes, stresses are

stepped up again and the cycle is repeated until the "fundamental limit of the

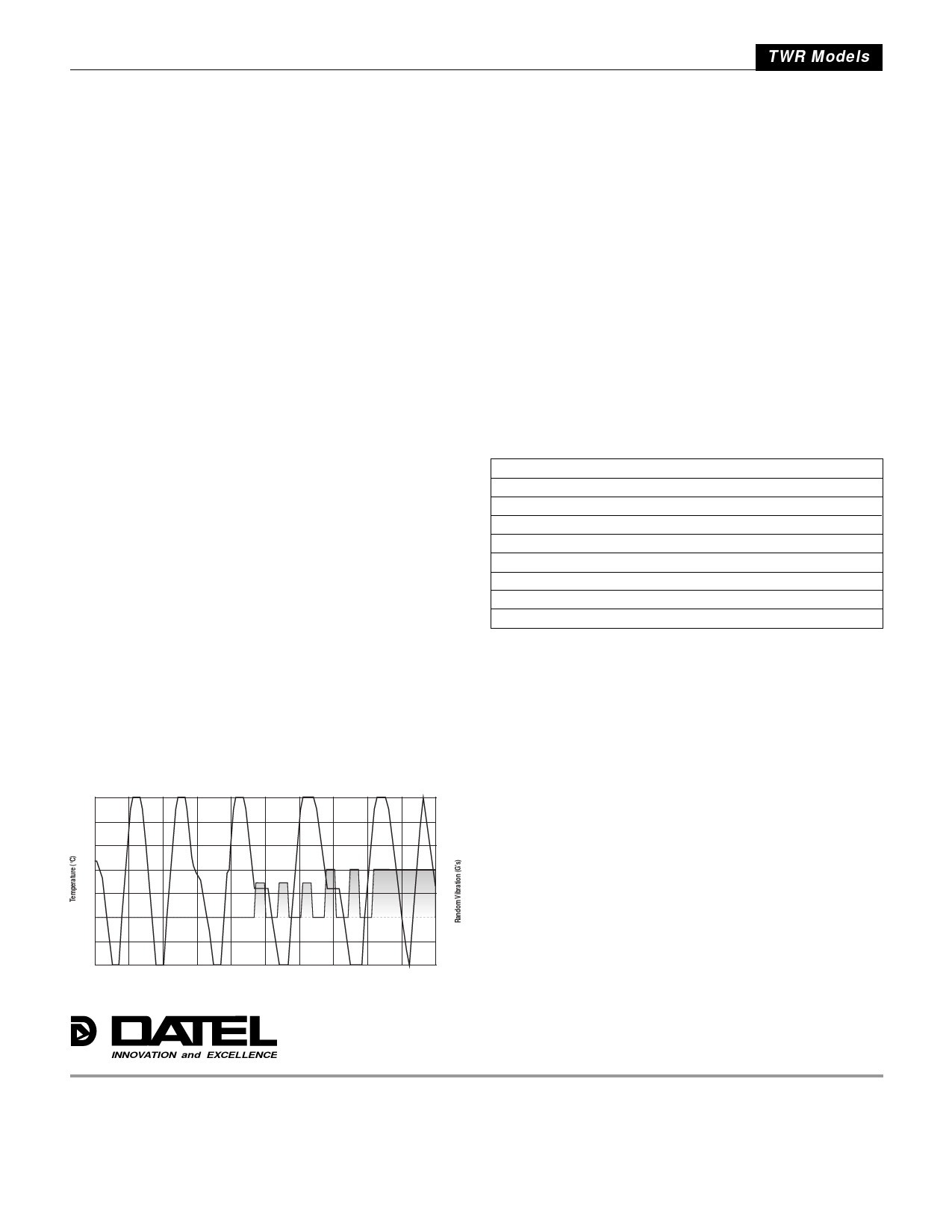

Typical HALT Profile

100

80

40

60

40

20

20

0

0

–20

–40

10

20

30

40

50

60

70

80

90

Test Time (minutes)

technology" is determined.

DATEL has invested in a Qualmark OVS-1 HALT tester capable of applying

voltage and temperature extremes as well as 6-axis, linear and rotational,

random vibration. A typical HALT profile (shown above) consists of thermal

cycling (–55 to +125°C, 30°C/minute) and simultaneous, gradually increasing,

random longitudinal and rotational vibration up to 20G’s with load cycling and

applied-voltage extremes added as desired. Many devices in DATEL’s new A-

Series could not be made to fail prior to reaching either the limits of the HALT

chamber or some previously known physical limit of the device. We also use

the HALT chamber and its ability to rapidly cool devices to verify their "cold-

start" capabilities.

Qualification

For each new product, electrical performance is verified via a comprehensive

characterization process and long-term reliability is confirmed via a rigorous

qualification procedure. The qual procedure includes such strenuous tests as

thermal shock and 500 hour life. Qual testing is summarized below.

Qualification Testing

Qualification Test

HALT

High Temperature Storage

Thermal Shock

Temperature/Humidity

Lead Integrity

Life Test

Marking Permanency

End Point Electrical Tests

Method/Comments

DATEL in-house procedure

Max. rated temp., 1,000 hours

10 cycles, –55 to +125°C

+85°C, 85% humidity, 48 hours

DATEL in-house procedure

+70°C, 500 hours*

DATEL in-house procedure

Per product specification

* Interim electrical test at 200 hours.

In-Line Process Controls and Screening

A combination of statistical sampling and 100% inspection techniques keeps

our assembly line under constant control. Parameters such as solder-paste

thickness, component placement, cleanliness, etc. are statistically sampled,

charted and fine tuned as necessary. Visual inspections are performed by

trained operators after pick-and-place, soldering and cleaning operations. Units

are 100% electrically tested prior to potting. All devices are temperature cycled,

burned-in, hi-pot tested and final-electrical tested prior to external visual

examination, packing and shipping.

Rapid Response to Problems

DATEL employs an outstanding corrective-action system to immediately

address any detected shortcomings in either products or processes. Whenever

our assembly, quality or engineering personnel spot a product/process problem,

or if a product is returned with a potential defect, we immediately perform a

detailed failure analysis and, if necessary, undertake corrective actions. Over

time, this system has helped refine our assembly operation to yield one of the

lowest product defect rates in the industry.

®

®

INNOVATION and EXCELLENCE

ISO 9001

REGISTERED

DS-0325 10/98

DATEL, Inc. 11 Cabot Boulevard, Mansfield, MA 02048-1151

Tel: (508) 339-3000 (800) 233-2765 Fax: (508) 339-6356

Internet: www.datel.com Email: sales@datel.com

Data Sheet Fax Back: (508) 261-2857

DATEL (UK) LTD. Tadley, England Tel: (01256)-880444

DATEL S.A.R.L. Montigny Le Bretonneux, France Tel: 01-34-60-01-01

DATEL GmbH München, Germany Tel: 89-544334-0

DATEL KK Tokyo, Japan Tel: 3-3779-1031, Osaka Tel: 6-354-2025

DATEL makes no representation that the use of its products in the circuits described herein, or the use of other technical information contained herein, will not infringe upon existing or future patent rights. The descriptions contained herein

do not imply the granting of licenses to make, use, or sell equipment constructed in accordance therewith. Specifications are subject to change without notice. The DATEL logo is a registered DATEL, Inc. trademark.

5