OKY-T/5-D12N-C 查看數據表(PDF) - Murata Power Solutions

零件编号

产品描述 (功能)

生产厂家

OKY-T/5-D12N-C Datasheet PDF : 21 Pages

| |||

OKY-T/3,T/5-D12 Series

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

Specification Notes, Cont.:

(5) The On/Off Control Input should use either a switch or an open collector/open drain transistor referenced

to -Input Common. A logic gate may also be used by applying appropriate external voltages which do not

exceed +Vin.

(6) Short circuit shutdown begins when the output voltage degrades approximately 2% from the selected

setting.

(7) For W5 models, the Input Voltage must exceed the Output Voltage at all times by the ratio of Vin >= (1.15 x

Vout). Please see the separate W5 data sheet.

(8) Output noise may be further reduced by adding an external filter. At zero output current, the output may

contain low frequency components which exceed the ripple specification. The output may be operated

indefinitely with no load.

(9) All models are fully operational and meet published specifications, including “cold start” at –40˚ C.

(10) Regulation specifications describe the deviation as the line input voltage or output load current is varied

from a nominal midpoint value to either extreme.

(11) Other input or output voltage ranges will be reviewed under scheduled quantity special order.

(12) Maximum PC board temperature is measured with the sensor in the center of the converter.

(13) Do not exceed maximum power specifications when adjusting the output trim.

(14) The maximum output capacitive loads depend on the the Equivalent Series Resistance (ESR) of the external

output capacitor and, to a lesser extent, the distance and series impedance to the load. Larger caps will

reduce output noise but may change the transient response. Newer ceramic caps with very low ESR may

require lower capacitor values to avoid instability. Thoroughly test your capacitors in the application. Please

refer to the Output Capacitive Load Application Note.

(15) Do not allow the input voltage to degrade lower than the input undervoltage shutdown voltage at all times.

Otherwise, you risk having the converter turn off. The undervoltage shutdown is not latching and will

attempt to recover when the input is brought back into normal operating range.

(16) The outputs are not intended to sink appreciable reverse current.

(17) “Hiccup” overcurrent operation repeatedly attempts to restart the converter with a brief, full-current output.

If the overcurrent condition still exists, the restart current will be removed and then tried again. This short

current pulse prevents overheating and damaging the converter. Once the fault is removed, the converter

immediately recovers normal operation.

Output Voltage Adustment

The output voltage may be adjusted over a limited range by connecting an

external trim resistor (Rtrim) between the Trim pin and Ground. The Rtrim

resistor must be a 1/10 Watt precision metal film type, ±1% accuracy or

better with low temperature coefficient, ±100 ppm/oC. or better. Mount the

resistor close to the converter with very short leads or use a surface mount

trim resistor.

In the tables below, the calculated resistance is given. Do not exceed the

specified limits of the output voltage or the converter’s maximum power

rating when applying these resistors. Also, avoid high noise at the Trim

input. However, to prevent instability, you should never connect any capaci-

tors to Trim.

OKY-T/3-D12, -T/5-D12

Output Voltage

5.0 V.

3.3 V.

2.5 V.

2.0 V.

1.8 V.

1.5 V.

1.2 V.

1.0 V.

0.7525 V.

Calculated Rtrim (KΩ)

1.472

3.122

5.009

7.416

9.024

13.05

22.46

41.424

∞ (open)

Resistor Trim Equation, D12 models:

RTRIM () = ______1_0_5_0_0___ –1000

VOUT – 0.7525V

www.murata-ps.com/support

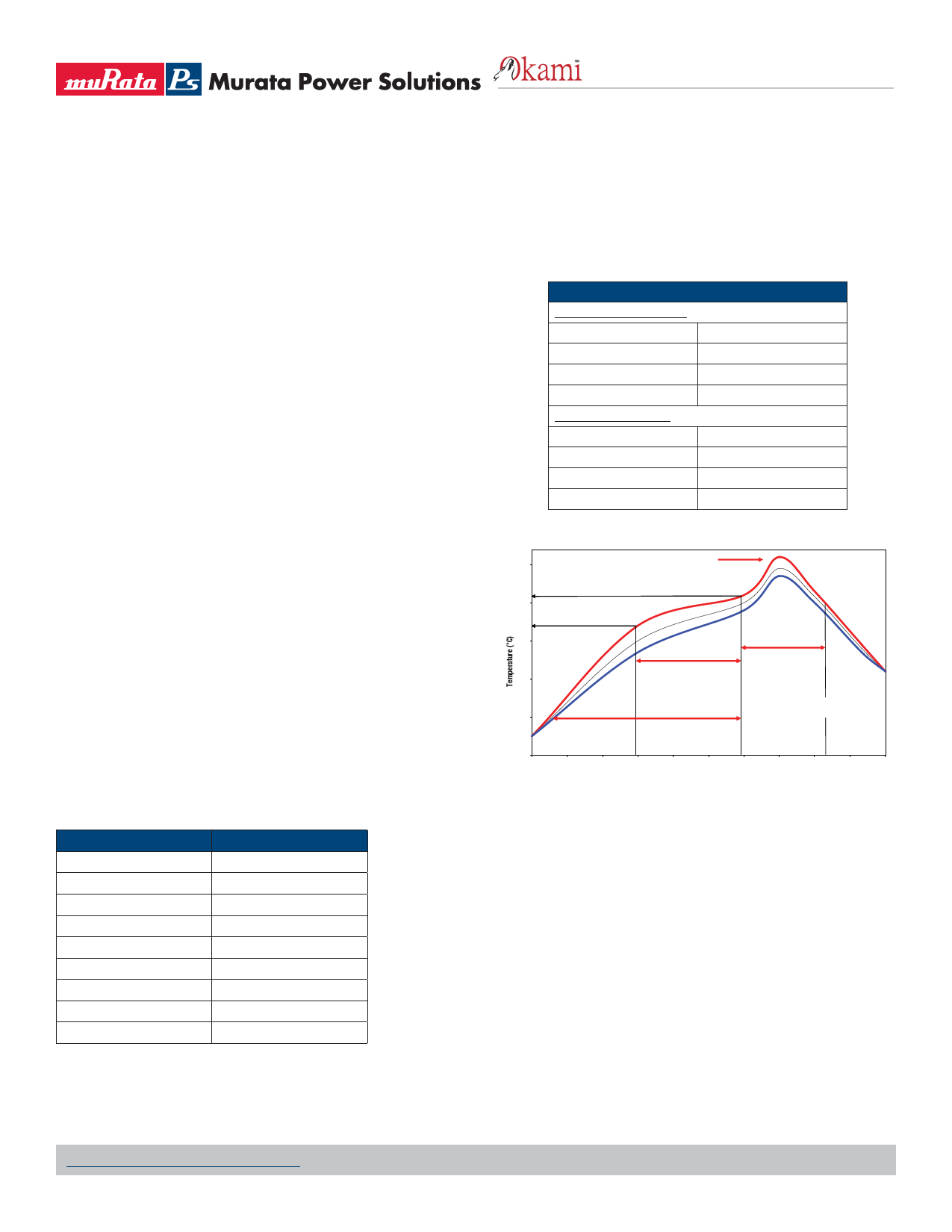

Soldering Guidelines

Murata Power Solutions recommends the specifications below when installing these

converters. These specifications vary depending on the solder type. Exceeding these

specifications may cause damage to the product. Your production environment

may differ therefore please thoroughly review these guidelines with your process

engineers.

Reflow Solder Operations for surface-mount products (SMT)

For Sn/Ag/Cu based solders:

Preheat Temperature

Less than 1 ºC. per second

Time over Liquidus

45 to 75 seconds

Maximum Peak Temperature 260 ºC.

Cooling Rate

Less than 3 ºC. per second

For Sn/Pb based solders:

Preheat Temperature

Less than 1 ºC. per second

Time over Liquidus

60 to 75 seconds

Maximum Peak Temperature 235 ºC.

Cooling Rate

Less than 3 ºC. per second

Recommended Lead-free Solder Reflow Profile

250

Peak Temp.

235-260° C

200

150

Reflow Zone

Soaking Zone

time above 217° C

120 sec max

45-75 sec

100

<1.5° C/sec

Preheating Zone

50

240 sec max

High trace = normal upper limit

Low trace = normal lower limit

0

0

30

60

90

120

150

180

210

240

270

300

Time (sec)

High trace = normal upper limit

Low trace - normal lower limit

MDC_OKY-T/3,T/5-D12 Series.B15 Page 5 of 21