LTC1159 查看數據表(PDF) - Linear Technology

零件编号

产品描述 (功能)

生产厂家

LTC1159 Datasheet PDF : 20 Pages

| |||

LTC1159

LTC1159-3.3/LTC1159-5

APPLICATIO S I FOR ATIO

0.20

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0

0

1

2

3

4

5

MAXIMUM OUTPUT CURRENT (A)

LTC1159 • F02

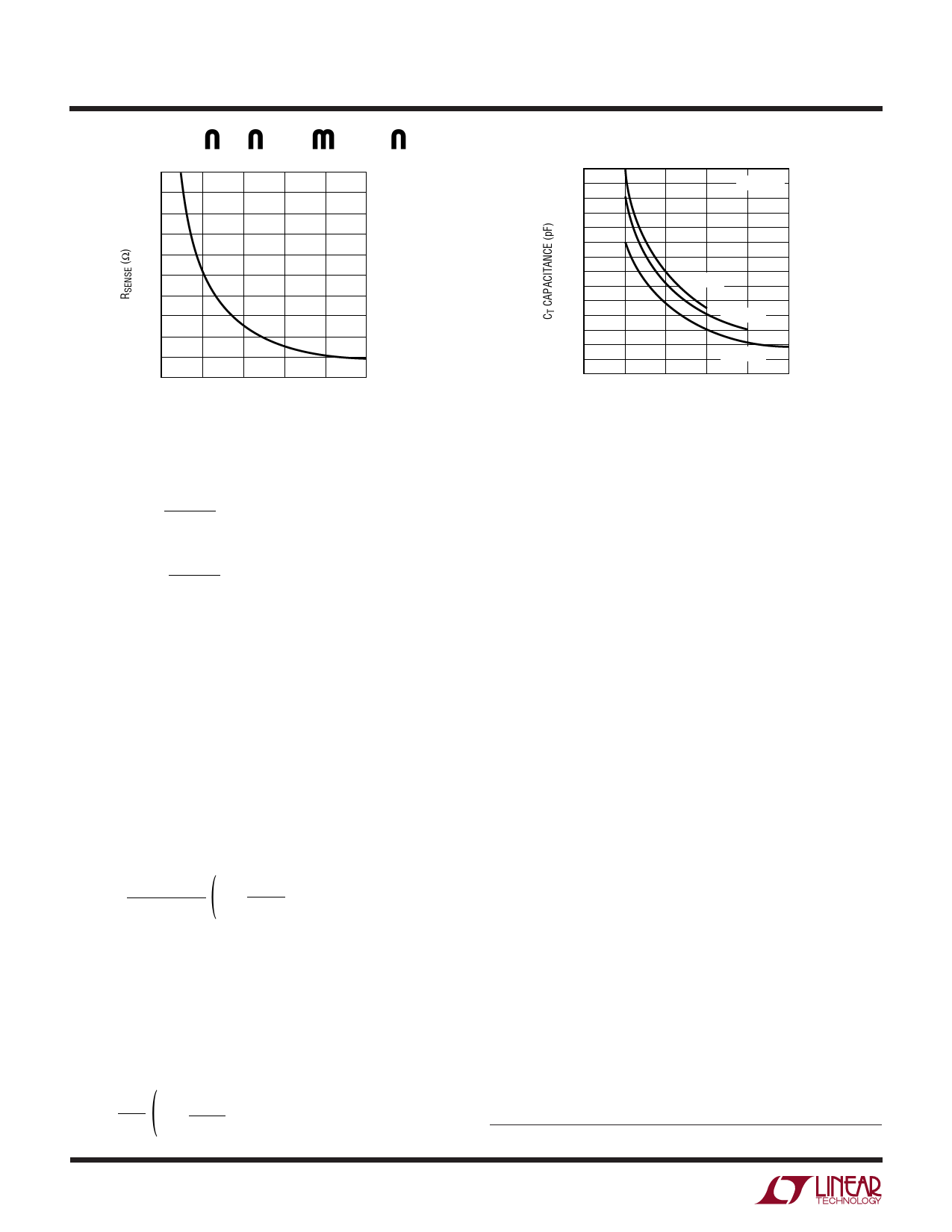

Figure 2. RSENSE vs Maximum Output Current

IBURST

≈

15mV

RSENSE

ISC(PK) =

150mV

RSENSE

The LTC1159 automatically extends tOFF during a short

circuit to allow sufficient time for the inductor current to

decay between switch cycles. The resulting ripple current

causes the average short-circuit current ISC(AVG) to be

reduced to approximately IMAX.

L and CT Selection for Operating Frequency

The LTC1159 uses a constant off-time architecture with

tOFF determined by an external timing capacitor CT. The

value of CT is calculated from the desired continuous mode

operating frequency, f:

) CT =

7.8 • 10–5

f

1–

VOUT

VIN

A graph for selecting CT versus frequency including the

effects of input voltage is given in Figure 3.

As the operating frequency is increased the gate charge

losses will be higher, reducing efficiency (see Efficiency

Considerations). The complete expression for operating

frequency is given by:

) f = 1 1 – VOUT

tOFF

VIN

1400

1200

1000

800

600

400

200

0

0

VOUT = 5V

VIN = 48V

VIN = 24V

VIN = 12V

50 100 150 200 250

FREQUENCY (kHz)

LTC1159 • F03

Figure 3. Timing Capacitor Selection

where tOFF = 1.3 • 104 • CT

Once the frequency has been set by CT, the inductor L

must be chosen to provide no more than 0.025V/RSENSE

of peak-to-peak inductor ripple current. This results in a

minimum required inductor value of:

LMIN = 5.1 • 105 • RSENSE • CT • VREG

As the inductor value is increased from the minimum value,

the ESR requirements for the output capacitor are eased at

the expense of efficiency. If too small an inductor is used,

the LTC1159 may not enter Burst Mode operation and

efficiency will be severely degraded at low currents.

Inductor Core Selection

Once the minimum value for L is known, the type of

inductor must be selected. High efficiency converters

generally cannot afford the core loss found in low cost

powdered iron cores, forcing the use of more expensive

ferrite, molypermalloy or Kool Mµ® cores. Actual core loss

is independent of core size for a fixed inductor value, but

it is very dependent on the inductance selected. As induc-

tance increases, core losses go down but copper (I2R)

losses will increase.

Ferrite designs have very low core loss, so design goals can

concentrate on copper loss and preventing saturation.

Ferrite core material saturates “hard,” which means that

inductance collapses abruptly when the peak design cur-

rent is exceeded. This results in an abrupt increase in

Kool Mµ is a registered trademark of Magnetics, Inc.

8