LTC690 查看數據表(PDF) - Linear Technology

零件编号

产品描述 (功能)

生产厂家

LTC690 Datasheet PDF : 18 Pages

| |||

LTC690/LTC691

LTC694/LTC695

APPLICATIONS INFORMATION

VHYSTERESIS

=

5V

R1

R3

=

850V

R3 ≈ 5.88 R1

Choose R3 = 300k and R1 = 51k. Also select R4 = 10k

which is much smaller than R3.

7.5V

=

1 . 3V

⎛

⎝⎜

1+51k

R2

–

(5V – 1.3V)51k⎞

1.3V(310k) ⎠⎟

R2 = 9.7kΩ, Choose nearest 5% resistor 10k and recalcu-

late VL,

VL

=

1.3V

⎛

⎝⎜1+

51k

10 k

–

(5V – 1.3V)51k⎞

1.3V(310k) ⎠⎟

=

7.32V

VH

=

1.3V

⎛

⎝⎜1+

51k

10k

+

51k ⎞

300k ⎠⎟

=

8.151V

(7.32V – 6.25V) = 10.7ms

100mV/ms

VHYSTERESIS = 8.151V – 7.32V = 831mV

The 10.7ms allows enough time to execute shutdown

procedure for microprocessor and 831mV of hysteresis

would prevent PFO from going low due to the noise of VIN.

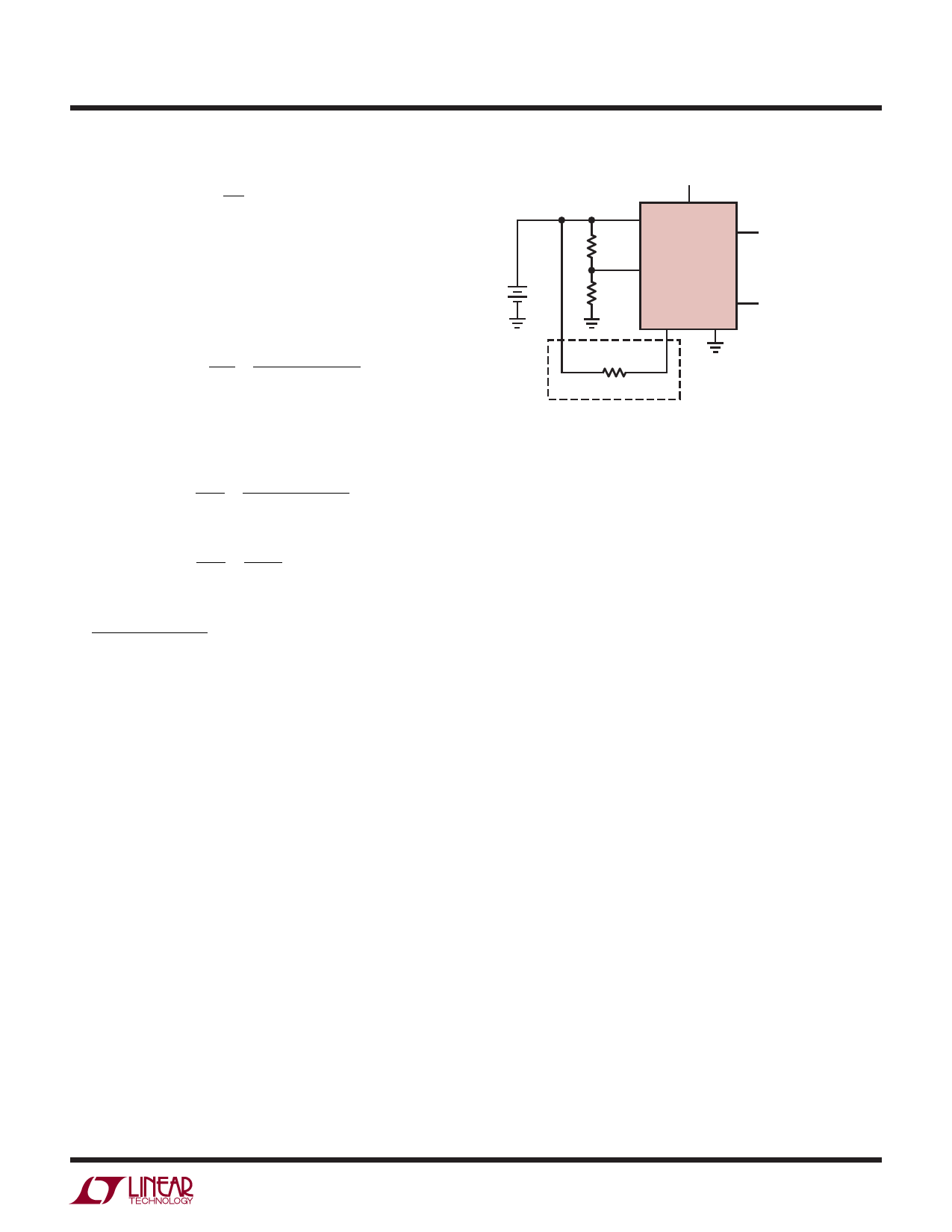

Example 2: The circuit in Figure 9 can be used to measure

the regulated 5V supply to provide early warning of power

failure. Because of variations in the PFI threshold, this

circuit requires adjustment to ensure the PFI comparator

trips before the reset threshold is reached. Adjust R5 such

that the PFO output goes low when the VCC supply reaches

the desired level (e.g., 4.85V).

Monitoring the Status of the Battery

C3 can also monitor the status of the memory back-up

battery (Figure 10). If desired, the CE OUT can be used to

apply a test load to the battery. Since CE OUT is forced high

in battery back-up mode, the test load will not be applied

to the battery while it is in use, even if the microprocessor

is not powered.

5V

R1

VBATT VCC

PFO

LOW-BATTERY SIGNAL

TO μP I/O PIN

1M

LTC691

PFI LTC695

3V

R2

1M

CE IN

I/O PIN

CE OUT GND

RL

690 F10

20k

OPTIONAL TEST LOAD

Figure 10. Back-Up Battery Monitor with Optional Test Load

Watchdog Timer

The LTC690 family provides a watchdog timer function

to monitor the activity of the microprocessor. If the

microprocessor does not toggle the Watchdog Input

(WDI) within a seleced timeout period, RESET is forced to

active low for a minimum of 35ms for the LTC690/LTC691

(140ms for the LTC694/LTC695). The reset active time is

adjustable on the LTC691/LTC695. Since many systems

can not service the watchdog timer immediately after

a reset, the LTC691 and LTC695 have longer timeout

period (1.0 second minimum) right after a reset is issued.

The normal timeout period (70ms minimum) becomes

effective following the first transition of WDI after RESET

is inactive. The watchdog timeout period is fixed at 1.0

second minimum on the LTC690 and LTC694. Figure 11

shows the timing diagram of watchdog timeout period and

reset active time. The watchdog timeout period is restarted

as soon as RESET is inactive. When either a high-to-low

or low-to-high transition occurs at the WDI pin prior to

timeout, the watchdog time is reset and begins to time

out again. To ensure the watchdog time does not time

out, either a high-to-low or low-to-high transition on the

WDI pin must occur at or less than the minimum timeout

period. If the input to the WDI pin remains either high or

low, reset pulses will be issued every 1.6 seconds typically.

The watchdog time can be deactivated by floating the WDI

pin. The timer is also disabled when VCC falls below the

reset voltage threshold or VBATT.

690fe

13