UWR-12/665-D5A-C 查看數據表(PDF) - Unspecified

零件编号

产品描述 (功能)

生产厂家

UWR-12/665-D5A-C Datasheet PDF : 6 Pages

| |||

UWR Series

Single Output, High Reliability, 2" x 1", 6-10 Watt, DC-DC Converters

Input Fusing

Certain applications and/or safety agencies may require the installation of

fuses at the inputs of power conversion components. For Murata Power

Solutions A-Series UWR 6-10 Watt DC/DC Converters, you should use slow-

blow type fuses with values no greater than the following:

VIN Range

D5A

D12A and D24E

D48A and D48E

Fuse Value

3A

2A

1A

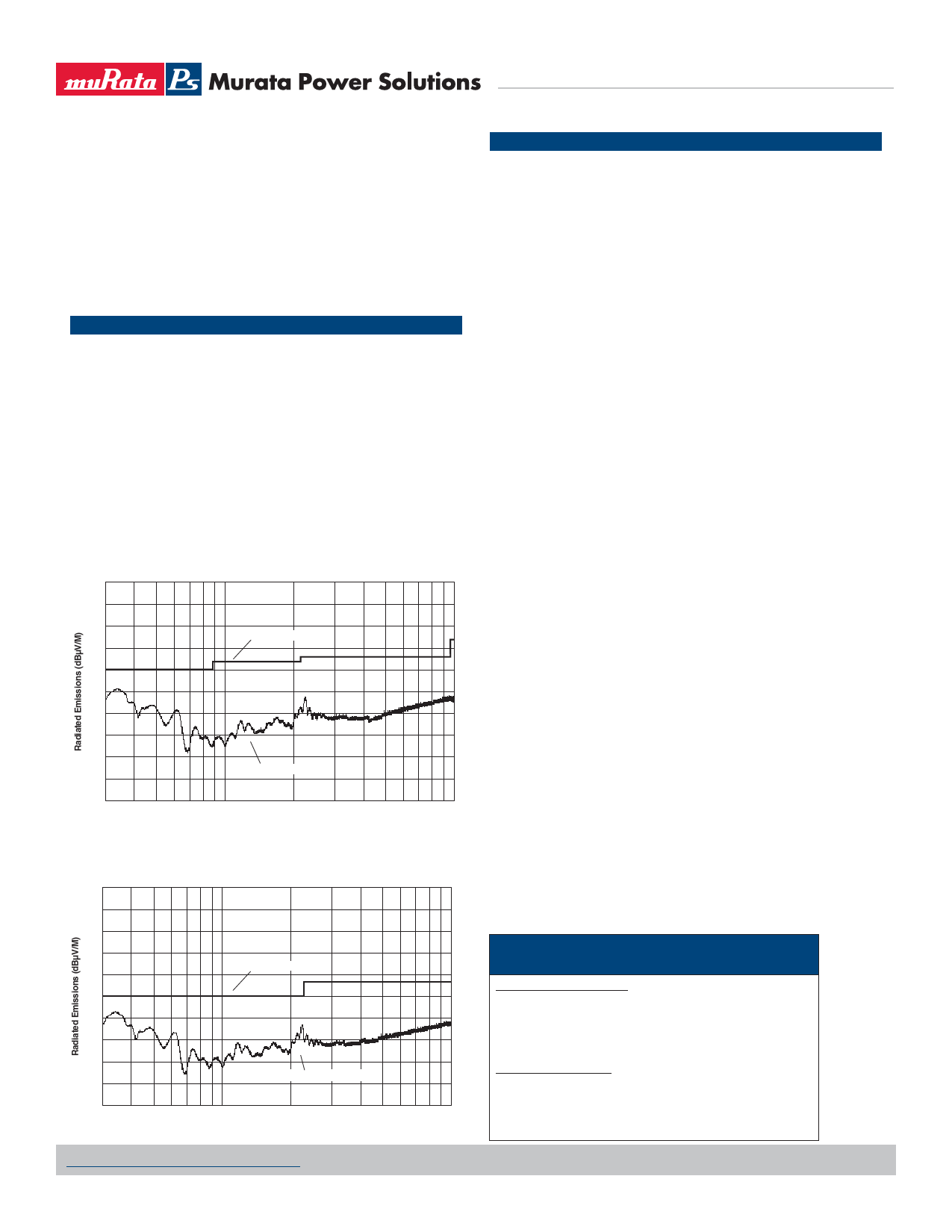

EMI RADIATED EMISSIONS

If you’re designing with EMC in mind, please note that all of Murata Power

Solutions' A-Series UWR 6-10 Watt DC/DC Converters have been character-

ized for radiated and conducted emissions in our new EMI/EMC labora-

tory. Testing is conducted in an EMCO 5305 GTEM test cell utilizing EMCO

automated EMC test software. Radiated emissions are tested to the limits

of FCC Part 15, Class B and CISPR 22 (EN 55022), Class B. Radiated emis-

sions plots to FCC and CISPR 22 for model UWR-12/665-D5A appear below.

UWR-12/665-D5A Radiated Emissions

FCC Part 15 Class B, 3 Meters

Converter Output = 12Vdc @ 620mA

80

70

60

FCC Class B Limit

50

40

30

20

10

0

Radiated Emissions

–10

–20

100

1000

Frequency (MHz)

UWR-12/665-D5A Radiated Emissions

EN 55022 Class B, 10 Meters

Converter Output = 12Vdc @ 620mA

80

70

60

50

EN 55022 Class B Limit

40

30

20

10

0

Radiated Emissions

–10

–20

100

Frequency (MHz)

1000

CUSTOM CAPABILITIES

Murata Power Solutions' world-class design, development and manu-

facturing team stands ready to work with you to deliver the exact power

converter you need for your demanding, large volume, OEM applications.

And ... we’ll do it on time and within budget!

Our experienced applications and design staffs; quick-turn prototype

capability; highly automated, SMT assembly facilities; and in-line SPC

quality-control techniques combine to give us the unique ability to design

and deliver any quantity of power converters to the highest standards of

quality and reliability.

We have compiled a large library of DC/DC designs that are currently used

in a variety of telecom, medical, computer, railway, aerospace and indus-

trial applications. We may already have the converter you need.

Contact us. Our goal is to provide you the highest-quality, most cost-

effective power converters available.

Quality and Reliability

The A-Series are the first DC/DC Converters to emerge from Murata Power

Solutions' new, company-wide approach to designing and manufacturing

the most reliable power converters available. The five-pronged program

draws our Quality Assurance function into all aspects of new-product

design, development, characterization, qualification and manufacturing.

Design for Reliability

Design for Reliability is woven throughout our multi-phased, new-product-

development process. Design-for-reliability practices are fully documented

and begin early in the new-product development cycle with the following

goals:

1. To work from an approved components/vendors list ensuring the use of

reliable components and the rigorous qualification of new components.

2. To design with safety margins by adhering to a strict set of derating

guidelines and performing theoretical worst-case analyses.

3. To locate potential design weaknesses early in the product-development

cycle by using extensive HALT (Highly Accelerated Life Testing).

4. To prove that early design improvements are effective by employing a

thorough FRACA (Failure Reporting Analysis and Corrective Action) System.

Soldering Guidelines

Murata Power Solutions recommends the specifications below when installing these

converters. These specifications vary depending on the solder type. Exceeding these

specifications may cause damage to the product. Be cautious when there is high atmo-

spheric humidity. We strongly recommend a mild pre-bake (100° C. for 30 minutes). Your

production environment may differ; therefore please thoroughly review these guidelines

with your process engineers.

Wave Solder Operations for through-hole mounted prod-

ucts (THMT)

For Sn/Ag/Cu based solders:

Maximum Preheat Temperature

115° C.

Maximum Pot Temperature

270° C.

Maximum Solder Dwell Time

7 seconds

For Sn/Pb based solders:

Maximum Preheat Temperature

105° C.

Maximum Pot Temperature

250° C.

Maximum Solder Dwell Time

6 seconds

www.murata-ps.com/support

MDC_UWR6-10W Series.E01 Page 5 of 6