BWR-5/6-3.3/7-D12L1 查看數據表(PDF) - DATEL Data Acquisition products

零件编号

产品描述 (功能)

生产厂家

BWR-5/6-3.3/7-D12L1

BWR-5/6-3.3/7-D12L1 Datasheet PDF : 12 Pages

| |||

XWR Series

33W, DUAL OUTPUT, MIXED-VOLTAGE DC/DC CONVERTERS

Absolute Maximum Ratings

Input Voltage:

Continuous:

"D12" Models

"D24" Models

"D48" Models

Transient (100msec): "D12" Models

"D24" Models

"D48" Models

23 Volts

42 Volts

81 Volts

25 Volts

50 Volts

100 Volts

Input Reverse-Polarity Protection ➁

"D12" Models

"D24" Models

"D48" Models

Input Current must be limited. 1 minute

duration. Fusing recommended.

6 Amps

4 Amps

2 Amps

Output Current ➁

Current limited. Devices can withstand

an indefinite output short circuit.

On/Off Control (Pin 4) Max. Voltages

Referenced to –Input (pin 2)

+VIN

Storage Temperature

–40 to +120°C

Lead Temperature (Soldering, 10 sec.) +300°C

These are stress ratings. Exposure of devices to any of these conditions may adversely

affect long-term reliability. Proper operation under conditions other than those listed in the

Performance/Functional Specifications Table is not implied, nor recommended.

TECHNICAL NOTES

5V & 3.3V Regulation

The BWR 33 Watt Series converters are designed such that both the 5V and

3.3V outputs share a common regulation feedback control loop. Though the

feedback loop is influenced by both outputs, the 3.3 Volt output is dominant.

As a result, the 3.3 Volt regulation (1%) is superior to the 5 Volt regulation (1.5%).

The converters are specified for load regulation of 10% to 100% loading and

for no-load to 100% loading. Operation below 10% of full load mandates

an increase in the regulation tolerance of ±0.5% for 3.3 Volt output and an

increase of ±1% for the 5 Volt output. A slight increase in switching noise

may also be observed for operation below 10% loading.

Operation with a full load on 3.3 Volt output and light to no load on 5 Volt

output is the most demanding for +5V regulation. Under such conditions the

internal "bleeder" circuit is activated to provide an internal load thereby keep-

ing regulation within the published specifications. The bleeder is activated

gradually so as not to cause any erratic behavior on the converters outputs. A

slight degradation in efficiency will occur while this internal load is activated.

Filtering and Noise Reduction

The BWR 33 Watt Series Converters achieve their rated ripple and noise

specifications with the use of 1µF output capacitors. In critical applications,

input/output noise may be further reduced by installing additional external

I/O capacitors. Input capacitors should be selected for bulk capacitance,

low ESR and high rms-ripple-current ratings. Output capacitors should be

selected for low ESR and appropriate frequency response. All caps should

have appropriate voltage ratings and be located as close to the converter

as possible.

Start-Up Time

The VIN to VOUT start-up time is the interval of time where the input voltage

crosses the turn-on threshold point, and the fully loaded output voltage enters

and remains within its specified accuracy band. Actual measured times will

vary with input source impedance, external input/output capacitance, and the

slew rate of the input voltages. The BWR-5/6-3.3/7 Series implements a

soft start circuit that limits the duty cycle of the PWM controller at power up,

thereby limiting the Input Inrush current.

The On/Off Control to VOUT start-up time assumes the converter has its

nominal input voltage applied but is turned off via the On/Off Control pin.

The specification defines the interval between the time at which the converter

is turned on and the fully loaded output voltage enters and remains within

its specified accuracy band. Similar to the VIN to VOUT start-up, the On/Off

Control to VOUT start-up time is also governed by the internal soft start

circuitry and external load capacitance.

Input Overvoltage/Undervoltage Shutdown and Start-Up Threshold

Under normal start-up conditions, devices will not begin to regulate until

the ramping-up input voltage exceeds the Start-Up Threshold Voltage (35V

for "D48" models). Once operating, devices will not turn off until the input

voltage drops below the Undervoltage Shutdown limit (34V for "D48" models).

Subsequent re-start will not occur until the input is brought back up to the

Start-Up Threshold. This built in hysteresis prevents any unstable on/off

situations from occurring at a single input voltage.

Input voltages exceeding the input overvoltage shutdown specification listed

in the Performance/Functional Specifications will cause the device to shut-

down. A built-in hysteresis of 0.6 to 1.6 Volts for all models will not allow the

converter to restart until the input voltage is sufficiently reduced.

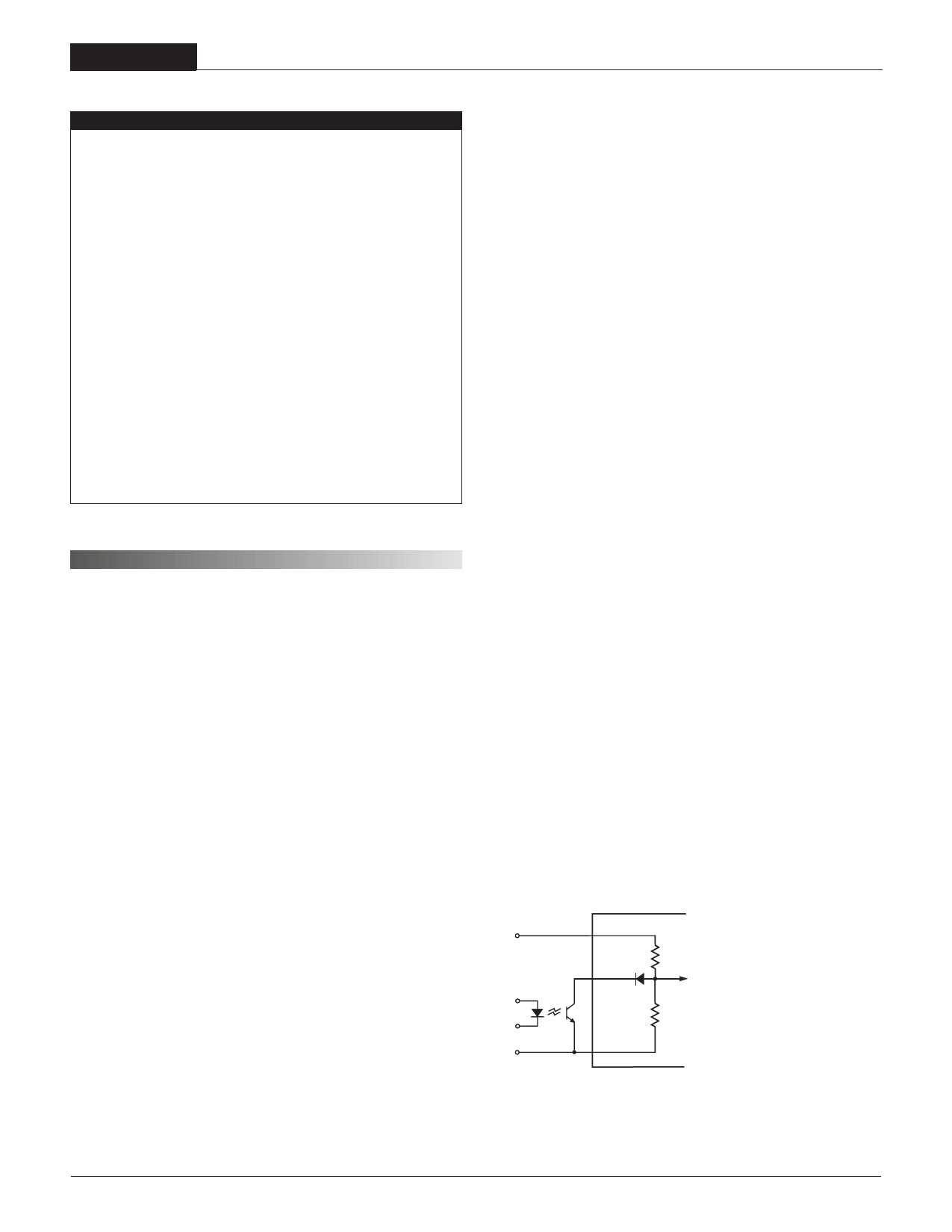

On/Off Control

The On/Off Control (pin 4) may be used for remote on/off operation. As

shown in Figure 1, the control pin is referenced to the –Input (pin 2) and will

be internally pulled to a high state. The standard BWR model (no suffix) is

designed so that it is enabled when the control pin is left open and disabled

when the control pin is pulled low (less than +0.8V relative to –Input).

Dynamic control of the on/off function is best accomplished with a mechanical

relay or an open-collector/open-drain circuit (optically isolated if appropriate).

The drive circuit should be able to sink approximately 1 mA for logic low.

The on/off control function is designed such that the converter can be

disabled while the input power is ramping up, and then "released" once the

input has stabilized.

1 +INPUT

RA

4

D12 RA = 34.8kΩ, RB = 6.83kΩ

ON/OFF

CONTROL

D24 RA = 100kΩ, RB = 9.74kΩ

D48 RA = 100kΩ, RB = 4.53kΩ

RB

2 –INPUT

Figure 1. Internal Circuitry for On/Off Control

4