GRM219R11E474JA88 查看數據表(PDF) - Murata Manufacturing

零件编号

产品描述 (功能)

生产厂家

GRM219R11E474JA88 Datasheet PDF : 30 Pages

| |||

No

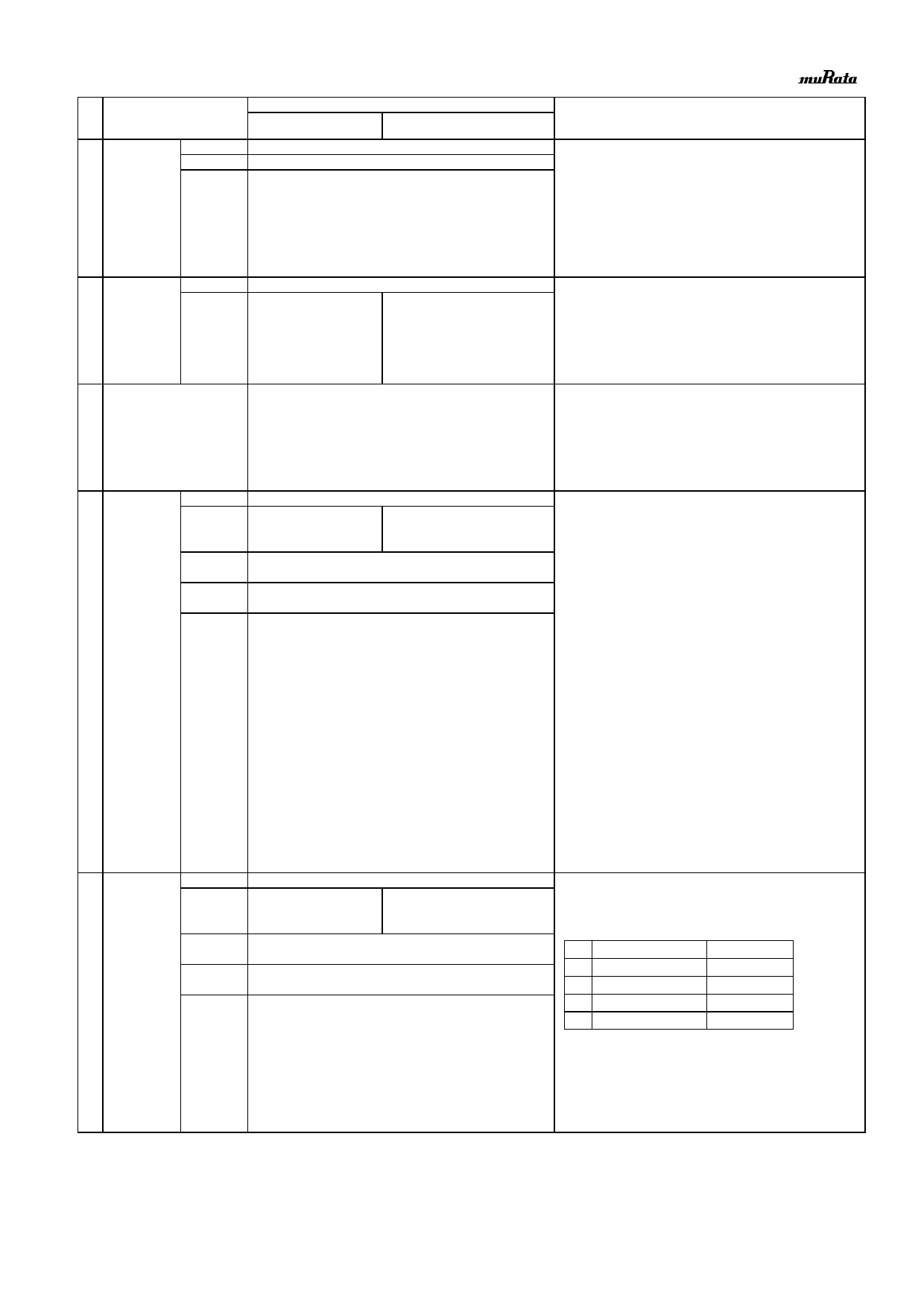

10 Vibration

Item

Appearance

Capacitance

Q or D.F.

Specification

Temperature

Compensating Type

High Dielectric

Constant Type

No defects or abnormalities.

Within the specified initial value.

Within the specified initial value.

Test Method

(Ref. Standard:JIS C 5101, IEC60384)

Solder the capacitor on the test substrate shown in Fig.3.

Kind of Vibration

: A simple harmonic motion

10Hz to 55Hz to 10Hz (1min)

Total amplitude

: 1.5mm

This motion should be applied for a period of 2h in each 3 mutually

perpendicular directions(total of 6h).

11 Substrate

Bending test

Appearance

Capacitance

Change

No defects or abnormalities.

Within +/-5% or +/-0.5pF

(Whichever is larger)

Within +/-10%

Solder the capacitor on the test substrate shown in Fig.1.

Pressurization method : Shown in Fig.2

Flexure

: 1mm

Holding Time

: 5+/-1s

Soldering Method

: Reflow soldering

12 Solderability

95% of the terminations is to be soldered evenly and continuously.

Test Method

Flux

Preheat

Solder

Solder Temp.

Immersion time

: Solder bath method

Solution of rojin ethanol 25(wt)%

: 80℃ to 120℃ for 10s to 30s

: Sn-3.0Ag-0.5Cu

: 245+/-5℃

: 2+/-0.5s

13 Resistance to

Soldering Heat

Appearance

Capacitance

Change

No defects or abnormalities.

Within +/-2.5% or +/- 0.25pF

(Whichever is larger)

Within +/-7.5%

Q or D.F.

Within the specified initial value.

I.R.

Within the specified initial value.

Voltage proof No defects.

<GRM03 size min.>

Test Method

: Solder bath method

Solder

: Sn-3.0Ag-0.5Cu

Solder Temp.

: 270+/-5℃

Immersion time

: 10+/-0.5s

Exposure Time

: 24+/-2h

Preheat

: GRM31 size max.: 120℃ to 150℃ for 1 min

GRM32 size : 100℃ to 120℃ for 1 min

and 170℃ to 200℃ for 1 min

· Initial measurement for high dielectric constant type

Perform a heat treatment at 150+0/-10°C for 1h and then

let sit for 24+/-2h at room temperature, then measure.

<GRM02 size only>

Test Method

: Reflow soldering (hot plate)

Solder

: Sn-3.0Ag-0.5Cu

Solder Temp.

: 270+/-5℃

Reflow Time

: 10+/-0.5s

Test Substrate

: Glass epoxy PCB

Exposure Time

: 24+/-2h

Preheat

: 120℃ to 150℃ for 1 min

· Initial measurement for high dielectric constant type

Perform a heat treatment at 150+0/-10°C for 1h and then

let sit for 24+/-2h at room temperature, then measure.

14 Temperature Appearance

Sudden Change Capacitance

Change

No defects or abnormalities.

Within +/-2.5% or+/- 0.25pF

(Whichever is larger)

Within +/-7.5%

Q or D.F.

Within the specified initial value.

I.R.

Within the specified initial value.

Voltage proof No defects.

Solder the capacitor on the test substrate shown in Fig.3.

Perform the five cycles according to the four heat treatments

shown in the following table.

Step

Temp.(C)

1 Min.Operating Temp.+0/-3

2

Room Temp.

3 Max.Operating Temp.+3/-0

4

Room Temp

Time (min)

30+/-3

2 to 3

30+/-3

2 to 3

Exposure Time

: 24+/-2h

· Initial measurement for high dielectric constant type

Perform a heat treatment at 150+0/-10°C for 1h and then

let sit for 24+/-2h at room temperature, then measure.

JEMCGS-0001U

3